What Is Masterbatch and Why Is It Essential in the Plastic Industry?

If you work in the plastics industry, you’ve probably heard the word “masterbatch” many times. It’s a small but powerful material that plays a crucial role in the color, quality, and durability of plastic products.

But what exactly is masterbatch? What is it made of? And why is it so important for manufacturers?

In this article from Asra Polymer, we’ll explain everything you need to know — in simple, practical language.

What Is Masterbatch?

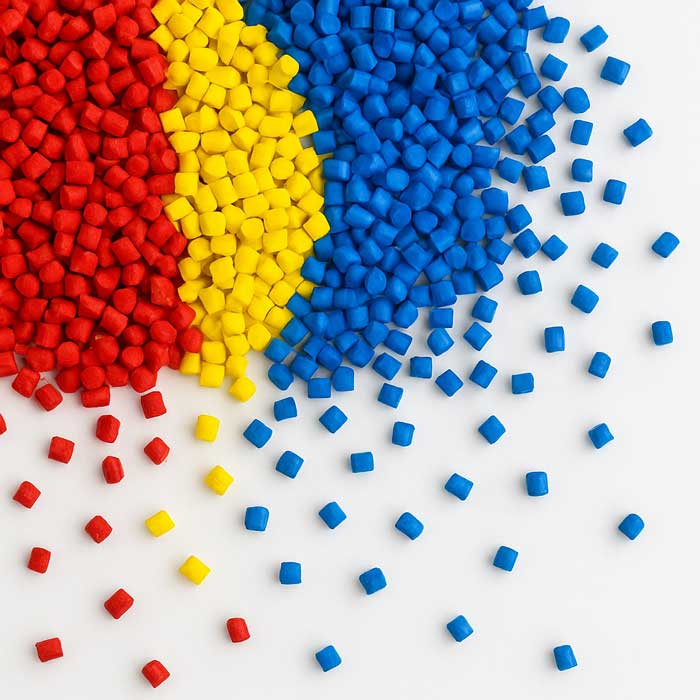

In simple terms, a masterbatch is a concentrated mixture of pigments or additives that are dispersed in a polymer carrier resin such as polyethylene (PE) or polypropylene (PP).

It comes in the form of small granules and is added to raw plastic materials during the extrusion or injection molding process to give the final product color or special properties.

Think of masterbatch as a “seasoning” for plastics — just a small amount can change the entire look or performance of the final product.

Main Components of a Masterbatch

A masterbatch typically consists of three main elements:

-

Carrier Resin:

The base polymer that carries and disperses pigments or additives.

It’s usually made of PE, PP, or PET — depending on the type of plastic being processed. -

Pigments or Additives:

These provide the color or functional properties, such as UV resistance, anti-static behavior, or biodegradability. -

Dispersing Agent:

Helps distribute the pigments evenly throughout the granule and prevents clumping.

Main Types of Masterbatch

1. Color Masterbatch

Used to give plastics their color. By mixing specific pigments, manufacturers can achieve a wide range of vibrant shades.

At Asra Polymer, our color masterbatches are produced in diverse tones with high coverage and excellent dispersion — perfect for packaging, automotive, and consumer products.

2. White Masterbatch

The most widely used type globally. It’s based on titanium dioxide (TiO₂), which provides brightness, opacity, and UV resistance.

White masterbatch is used in films, bottles, household items, and injection-molded products.

3. Black Masterbatch

Formulated with carbon black, this type not only provides deep black color but also enhances UV protection and mechanical strength.

It’s widely used in cables, pipes, agricultural films, and automotive parts.

Why Use Masterbatch Instead of Powder Pigments?

Compared to powdered or liquid colorants, masterbatch offers many advantages:

-

Cleaner production — no dust or mess.

-

More accurate color control — consistent results in every batch.

-

Better thermal stability — color doesn’t change under high temperatures.

-

Less material waste — higher efficiency during processing.

Over time, these benefits translate into lower production costs and more reliable product quality.

What Determines Masterbatch Quality?

A high-quality masterbatch depends on several key factors:

-

Pigment Quality: High transparency and color stability.

-

Uniform Dispersion: The color must be evenly distributed throughout the product.

-

Carrier Compatibility: Proper matching with the main polymer ensures better bonding and durability.

-

Optimal Dosage: Usually, 1–5% of masterbatch is enough to achieve the desired color.

The Masterbatch Production Process

Producing masterbatch involves several precise steps:

-

Mixing pigments and carrier resin

-

Melting and blending them in an extruder

-

Cutting the extruded strands into small granules

-

Cooling, drying, and packaging

Temperature and pressure must be carefully controlled to ensure perfect pigment dispersion.

Key Advantages of Using Masterbatch

-

Consistent, long-lasting color across all surfaces

-

Reduced waste and production costs

-

Maintained mechanical and chemical properties of polymers

-

Improved resistance to heat, light, and impact

-

Custom color and formulation options for each client

Asra Polymer — Your Reliable Masterbatch Supplier

Asra Polymer specializes in the production and supply of color, white, and black masterbatches.

Using high-quality raw materials and advanced compounding technology, our products provide excellent coverage, UV resistance, and process stability.

They are suitable for injection molding, film extrusion, blow molding, and pipe manufacturing applications.

Conclusion

Masterbatch may look small, but its impact is huge.

The right masterbatch can enhance the appearance, durability, and cost-efficiency of your plastic products.

For bright colors, brilliant whites, deep blacks, and reliable performance,

Asra Polymer’s masterbatches are your trusted solution for consistent quality and long-term value.