Additive Masterbatches: A Solution for Stronger and Greener Products

The polymer industry is constantly seeking ways to improve the quality and performance of its products. In this pursuit, additive masterbatches have emerged as an innovative and effective solution, transforming both the production process and the final properties of plastic products. Masterbatches are concentrated mixtures of additives in a polymer base, which are added during production to impart specific properties to the final product. This technology not only enhances performance but also reduces production costs and promotes environmental sustainability.

With increasing attention to green and eco-friendly products, the role of additive masterbatches in achieving sustainable industrial goals has become increasingly important. This article explores the types of additive masterbatches, their benefits, and their industrial applications.

What is a Masterbatch?

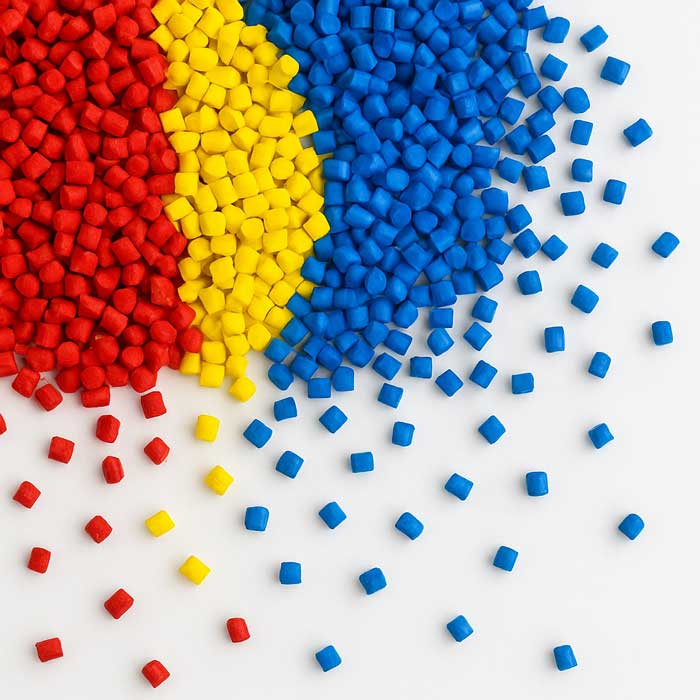

A masterbatch is a concentrated mixture containing one or more active additives in a polymer base. These additives can include colorants, heat stabilizers, antioxidants, UV stabilizers, lubricants, antimicrobial agents, and fillers. Masterbatches are typically supplied in powder or pellet form and are added to the base polymer during extrusion, injection molding, or film production processes.

Compared to directly adding additives to the polymer, using a masterbatch offers several advantages:

-

Uniform dispersion of additives throughout the polymer matrix

-

Reduced direct contact with chemicals for operators

-

Precise control of additive concentration and prevention of waste

-

Ease of storage and handling

Types of Additive Masterbatches

Masterbatches can be classified into several categories depending on the type of additive and intended purpose:

1. Color Masterbatches

Color masterbatches are used to achieve uniform and vibrant colors in plastic products. They typically contain organic or inorganic pigments and can also enhance the optical properties and UV resistance of the product.

2. Functional Masterbatches

Functional masterbatches improve the physical and chemical properties of polymers. Examples include:

-

UV Stabilizer Masterbatches: Increase resistance to sunlight, reducing discoloration and brittleness

-

Antimicrobial Masterbatches: Inhibit the growth of bacteria and fungi

-

Anti-Static Masterbatches: Reduce surface static electricity in products

-

Flow and Processing Aid Masterbatches: Facilitate injection molding and extrusion processes

3. Filler and Reinforcing Masterbatches

These masterbatches contain fillers such as talc, calcium carbonate, or natural fibers to increase rigidity, mechanical strength, and reduce production costs. They also help reduce the consumption of the base polymer, decreasing environmental impact.

Benefits of Using Additive Masterbatches

Using additive masterbatches improves not only the quality of the product but also offers economic and environmental advantages:

1. Enhanced Mechanical and Chemical Properties

Additive masterbatches can improve tensile, impact, and thermal resistance of polymers, making final products suitable for demanding industrial applications.

2. Waste Reduction and Efficiency Improvement

Masterbatches ensure uniform dispersion of additives, preventing localized deficiencies or excesses. This reduces waste and increases production efficiency.

3. Ease of Production

Masterbatches are ready-to-use pellets or powders, eliminating the need for complex and time-consuming measurements of individual additives.

4. Eco-Friendly and Sustainable Products

Functional and reinforcing masterbatches allow reduced use of base polymers and incorporation of recycled or natural materials, leading to greener products and lower environmental impact.

Industrial Applications of Additive Masterbatches

Masterbatches are widely used in various industries to produce high-performance and high-quality products. Key applications include:

1. Packaging

In packaging, UV and antimicrobial masterbatches increase shelf life, protect food products from sunlight, and inhibit microbial growth.

2. Construction

Reinforcing and filler masterbatches enhance the mechanical strength and durability of PVC profiles, pipes, and construction components.

3. Automotive

Heat-resistant and UV-stabilized masterbatches improve the longevity and appearance of both interior and exterior automotive parts.

4. Electronics and Home Appliances

Anti-static and heat-resistant masterbatches are crucial for electronic components, cables, and household appliances, ensuring safety and durability.

Conclusion

Additive masterbatches are a powerful tool for producing stronger, higher-quality, and more environmentally friendly products. They enable polymer manufacturers to enhance mechanical, chemical, and optical properties, optimize production processes, and reduce waste.

Given the growing demand for recycled and sustainable materials, additive masterbatches will play a key role in the future of the polymer industry. Using this technology not only brings economic advantages but also supports environmental goals and sustainable development.

Asra Polymer offers a wide range of color, functional, and reinforcing masterbatches, ready to support industries in producing high-quality, eco-friendly products.